Sleeves and their ‘hard reality’: Composite versus steel on steel pipes

The contribution compares two types of repairs of high-pressure gas pipelines and oil pipelines. One is a sleeve made of steel combined with composite filling and the other is a composite sleeve made of carbon fibre and epoxy resin.

The two repairs were compared during an experiment in which a DN 500 pipe sample with artificial defects was repaired by those sleeves.

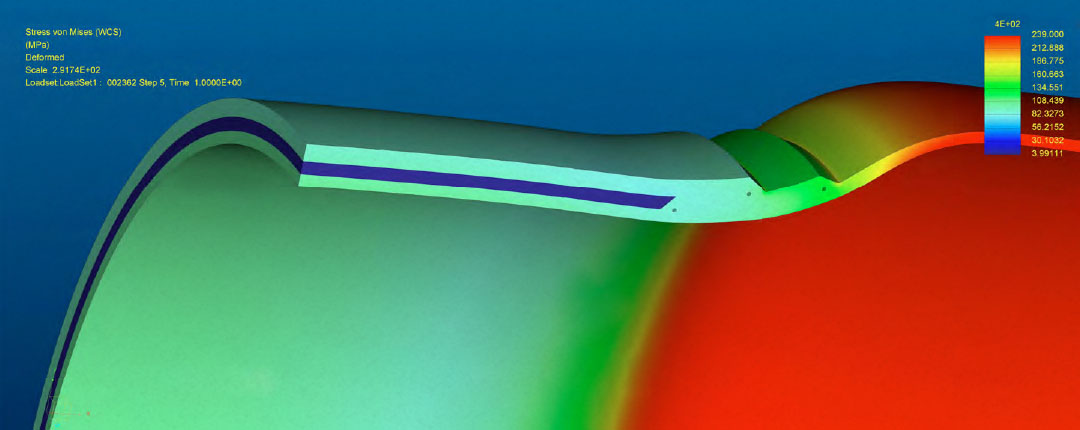

Graphs in the article show the circumferential deformation on the defect’s surface under each sleeve after pressurisation. An addition to the experiment was a software model of a steel sleeve with composite filling, based on the Finite Element Method.

The contribution is intended to offer an idea of where combinations of steel and composite materials are or are not appropriate for elements exposed to high loads, such as high-pressure pipelines.

Read more in the article Sleeves and their ‘hard reality’: Composite versus steel on steel pipes (PDF, Czech language, 1059 kB).