Systematic approach streamlines natgas pipeline pressure increase

A sequence consisting of internal inspection, elimination of major defects, and subsequent pressure testing is the most efficient way to ensure the integrity and increase the operating pressure of aging high-pressure natural gas transmission pipelines.

Gas flow through Polish pipeline systems has been gradually changing to west–to–east from east–to–west, the direction it's flowed in the last few years. This transition has led to a requirement to increase the capacity of gas pipelines to transport gas at 7.4 MPa (1,073.28 psia) in some Polish regions.

This increase is achieved not only by building new high-pressure pipelines but also by integrating older revalidated pipelines operated in the past at lower pressures. An example of this comprehensive approach was revalidation of the 55-km (34-mile) gas pipeline DN 400 in southwestern Poland.

Revalidation included the following steps:

- Cleaning the pipeline

- Performing in-line MFL inspection

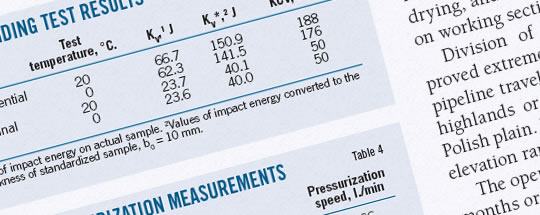

- Material testing of samples taken from the original pipeline

- Model integrity testing of pipe body vessel taken from the original pipeline

- Designing working procedures for integrity test

- Preparing the pipeline for testing

- Integrity testing, drying by super dry air

- Final reporting

Read more in the article Systematic approach streamlines natgas pipeline pressure increase (PDF, 583 kB).