Research into gas pipeline vacuum drying

For gas pipeline drying under TPG 702 11, techniques such as super dry air and high vacuum are currently being used. While the super dry air technique is relatively well described and well managed in operating terms, the high vacuum technique continues to bring a number of ambiguities and question marks.

The preparations for an amendment to this standard included experiments carried out with a view to clarifying some of the problems and describing them better and, potentially, proposing changes to standardised procedures in order to improve the efficiency of the high vacuum drying process while preserving the reliability of the technique and the results achieved.

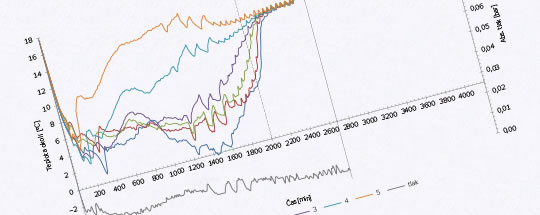

The measured data suggests that water drying from steel piping using high vacuum also takes place quantitatively from the solid phase and, at low ambient temperatures, even much better than drying when the liquid phase is maintained.

The main advantage of ice consists in creating a steep temperature gradient in the system, which ensures faster absorption of heat from the surroundings. As regards the checking of pipe dryness, ice behaves similarly to water, and so the pressure in the system increases in tens of minutes and there is no need to keep extremely long periods for verification, up to hundreds of hours in extreme cases.

Following the evaluation of results, modified principles for high vacuum drying have been drawn up; they will be incorporated into the amendment to TPG 702 11.

Read more in the article Research into gas pipeline vacuum drying (PDF, Czech language, 497 kB).