Hydrostatic testing

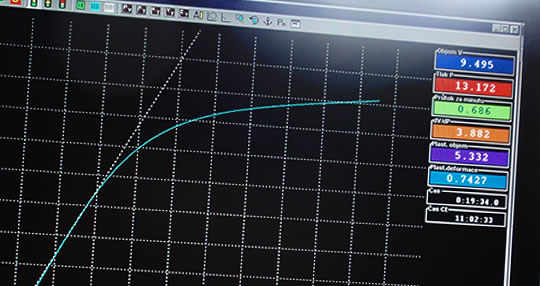

CEPS operates complete sets of equipment for flooding, hydrostatic testing and dewatering of high pressure pipelines up to 56″ including high pressure and high capacity pumps and unique computerized test monitoring and control systems based on the highly accurate metering equipment.

Our field engineers with over 25 years of experience using this state of the art equipment do validate the pipeline integrity with the highest level of safety and reliability. We offer hydraulic tests according to any required specification including stress-tests where the controlled pressurization creates a strain in the pipeline wall in the range of the real yield stress of the steel.

CEPS provides turn-key commissioning services including engineering studies and/or specification development, pipeline cleaning and gauging, chemical treatment of test water, pipeline flooding, hydrostatic pressure testing, tightness tests, pipeline dewatering and pipeline air drying and vacuum drying.

Our pressure testing equipment and procedures comply with requirements of commonly used international standards EN 1594 (EU), ASME B31.8 Code, ASME B31.4 Code, The US Federal Safety Regulation for Pipelines or any other national standards, for example, DVGW G 469 (Germany), NEN 3650 (The Netherlands), PN-M-34503 (Poland) as well as the German standard VdTŰV Merkblatt 1060, or the Czech standard TPG 702 04 for stress-tests.

Our on-line visualization, recording, and control systems allow to stop the tests as soon as the pressure target value or calculated acceptable added volume limit is reached.