Online measurement of pipeline flow parameters

Knowledge of flow characteristics of pipeline enables to properly design and operate pipeline systems, to assess the state of the inner surface of the pipe and to set the interval of cleaning pipelines based on actual needs.

Sample gas from pipelines and detection of hydrogen

Why to measure hydraulics of pipeline?

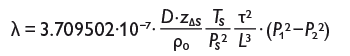

Hydraulic properties of the pipeline defined by friction factor (of flow) are one of the fundamental parameters affecting projection and economy of the pipeline operation.

Determination of value of friction factor is already very important in the design stage. Under the given specific transit conditions the size of this coefficient depends the pressure loss in a pipeline. On the basis of value of pressure loss the proper dimension of pipeline is determined and – when pipeline is equipped with compressor stations – the compression work needed for the elimination of pressure loss, and thus determined the necessary working power installed at compressor stations. Considering the high cost of construction of the pipelines and the compressor stations it is clear, how important is to determine the necessary pipeline dimension and working power at the compressor stations correctly.

Knowing the value of the friction factor for individual sections of pipeline is also very useful for already operating pipelines. Value and especially changes in the value of the coefficient can show the status of the internal pipe surface and its changes, for example in connection with regular determination of operating effectiveness performed during pipeline cleaning. During regular operating cleaning of pipeline relatively large quantities of gas are irreversibly lost by blowing into the atmosphere when pig is rolling into the trap. This is the reason for minimizing frequency of cleaning to actual needs that are currently indicated by an increase of friction coefficient over the allowable limit.

Measurement and record of pressure at the beginning of the measured section

Sampling probe inserted at full pressure to the level of pipeline axis

The results of measurements of hydraulic parameters of pipeline in operation can determine the probable value of friction coefficient for newly designed pipelines and it may allow an estimation of changes in hydraulic behaviour of the pipeline after its commissioning. This knowledge significantly affects reliability of determination of required compression work and resulting amount of installed capacity.

Knowledge of the real values of hydraulic resistance of individual lines makes considerably more accurate the modelling of the operation which is crucial for the trade with free capacity at high-pressure pipelines.

Interested to find solution that fits your needs?

Contact us on +420 241 021 519, or let us know at info@ceps-as.cz